Innovation in Recycling

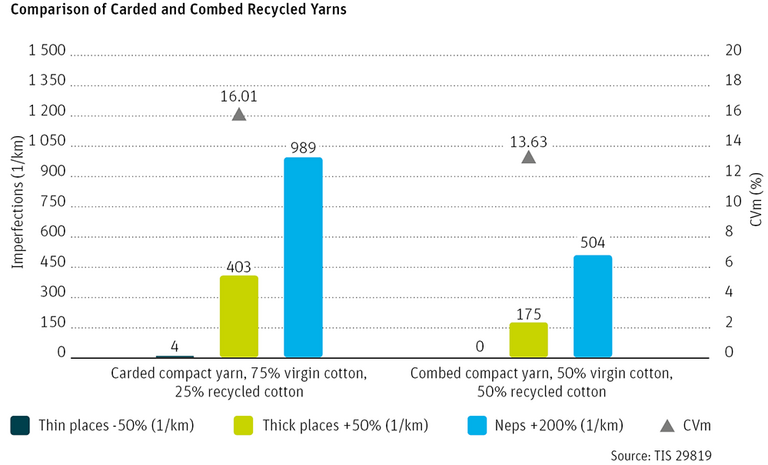

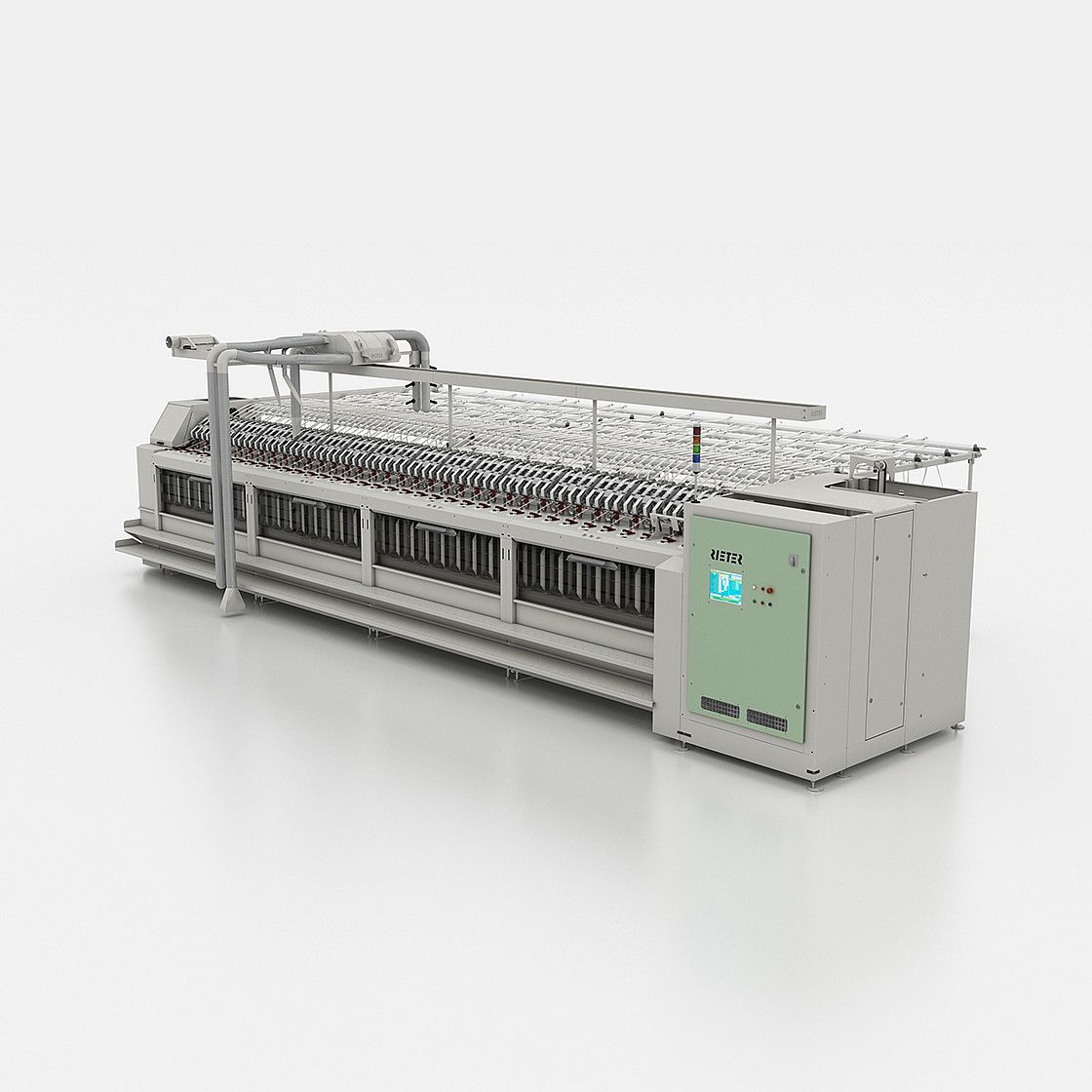

The combed process is a standard process which is widely used in the industry to improve the quality of virgin cotton. It enables the spinning of finer yarns with a higher tenacity as well as lower imperfections and unevenness. With the potential of reducing the short-fiber content and the number of neps, it is a very interesting process to be also used for recycled cotton blends. Rieter conducted several trials which show the successful use of the combed process for spinning ring and compact yarns from blends of mechanically recycled and virgin cotton.