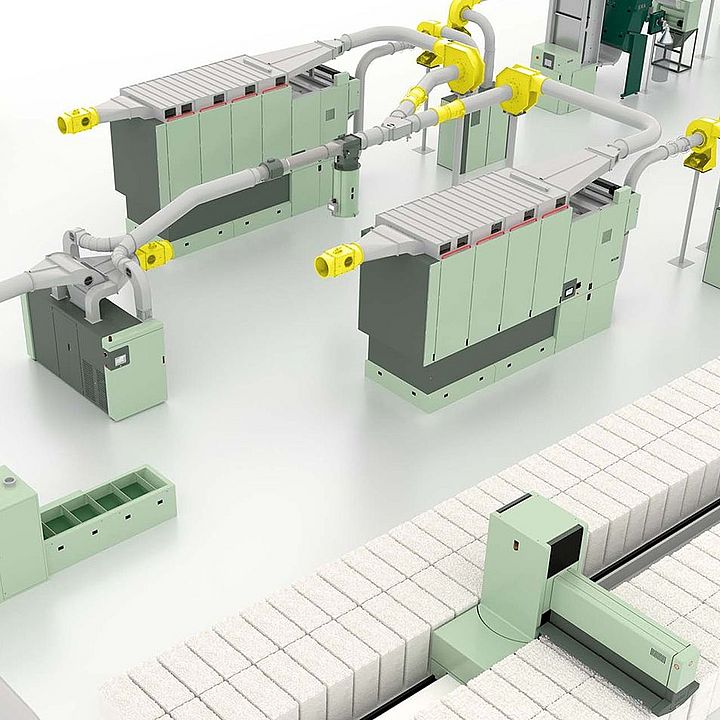

Perfectly coordinated technology from fiber to sliver

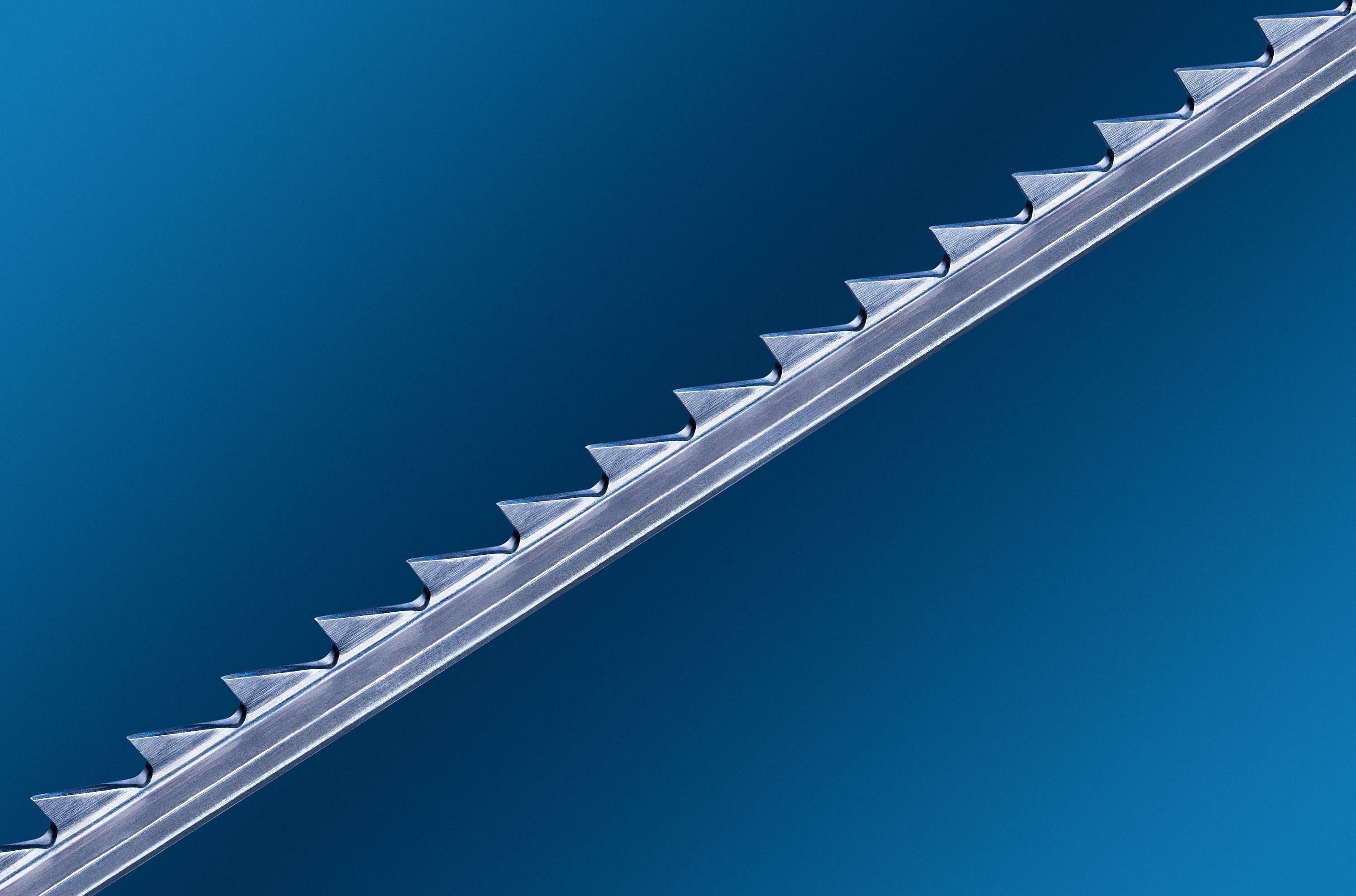

Rieter fiber preparation guarantees gentle opening, efficient cleaning and intensive blending of the fibers. Operator-friendly adjustable settings and high cleaning efficiency are the best qualifications for high yarn quality. The greatest possible raw material utilization is achieved by optimally coordinated individual components in the blowroom line. Rieter cards convince by their excellent quality values at highest production, based on the proven 1.5 m working width and the integrated grinding system for card clothing.